Product Applications:

Widely used for drying foods such as rice flour, cereal, α-starch, and potato whole powder, as well as viscous materials in chemical, environmental protection, pharmaceutical, and feed industries. Finished products can be made into flake, powder, and granular forms.

Working Principle:

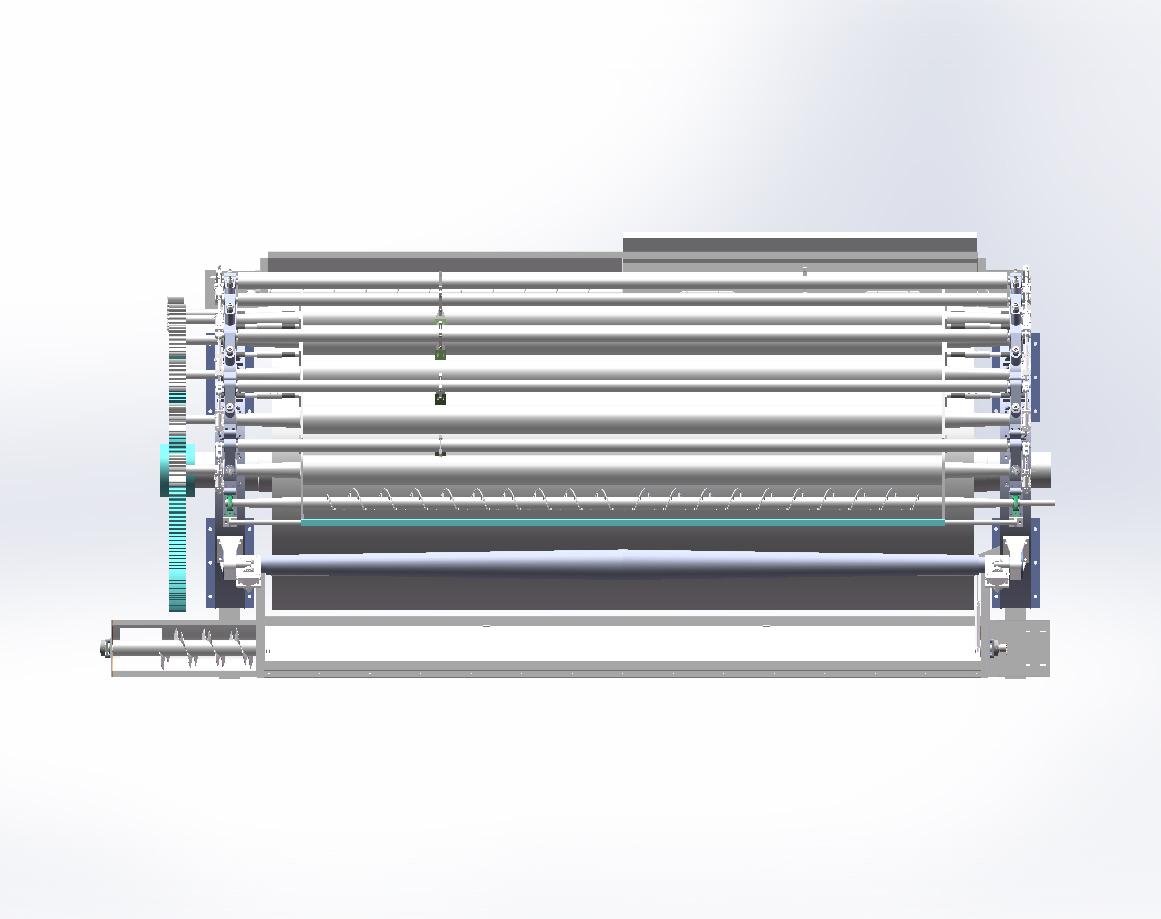

This product comes in various forms, such as single drum and double drum, with different working principles. The basic principle is as follows: saturated steam (or heat transfer oil) is passed through the middle of the main drum, and the material is coated on the drum surface in different ways for heating, ripening, and skinning. A specially designed scraper removes the material and transports it to the next process for finished product treatment.

Processing Examples:

Instant nutritional rice flour, instant cereal, ready-to-eat cereal breakfast, potato snowflake whole powder, various pre-gelatinized (α) starches (wheat, potato, cassava, corn, sweet potato, banana taro, rice, lily, lotus root, etc.), yeast, fish and shrimp feed, various milk powders and whey powders, gums, pigments, adhesives, fruit and vegetable juices, eggs, chemical slurries, environmental wastewater, sludge, etc.

Single Drum Dryer

Model 0505 1010 1015 1022 1030 1522 1530 1540 2040 Drum Dia(mm) Φ500 Φ1000 Φ1000 Φ1000 Φ1000 Φ1500 Φ1500 Φ1500 Φ2000 Length(mm) 500 1000 1500 2250 3050 2250 3050 4000 4000 Dry Area(㎡) 0.75 3.14 4.71 7.07 9.58 10.60 14.37 18.84 25.12 Weight(T) 1 3 8 11 14 17 22 25 36 Space(L×W)(㎡) 1.2×1 2.5×2 3.5×3 4.8×3 5.7×3 5.7×3.3 6×3.3 6.5×3.3 7×4.6 Net Heighth(m) 2.5 3.5 5.5 6 6 6.5 7 7.5 8 Power(kW) Max 5.5 11 15 22 30 37.5 45 55 75 Min 1.5 2.2 3 4 4 5 7.5 7.5 11

Double Drum Dryer

| Model | 0505 | 1010 | 1015 | 1022 | 1030 | 1522 | 1530 | 1540 | |

| Drum Dia(mm) | Φ500 | Φ1000 | Φ1000 | Φ1000 | Φ1000 | Φ1500 | Φ1500 | Φ1500 | |

| Length(mm) | 500 | 1000 | 1500 | 2250 | 3050 | 2250 | 3050 | 4000 | |

| Drying Area(㎡) | 1.5 | 6.28 | 9.42 | 14.14 | 19.16 | 21.20 | 28.74 | 37.68 | |

| Weight(T) | 1.7 | 9 | 11 | 17 | 25 | 35 | 42 | 47 | |

| Space(L×W)(㎡) | 1.2×1.5 | 2.5×2 | 3.5×3.6 | 4.8×3.6 | 5.7×3.6 | 5.7×5 | 6×5 | 6.5×5 | |

| Net Heighth(m) | 2.5 | 3.5 | 5 | 6 | 6 | 6.5 | 7 | 7.5 | |

| Power(kW) | Max | 7.5 | 11 | 15 | 22 | 22 | 45 | 75 | 80 |

| Min | 1.5 | 2.2 | 3 | 3 | 5.5 | 7.5 | 15 | 22 | |

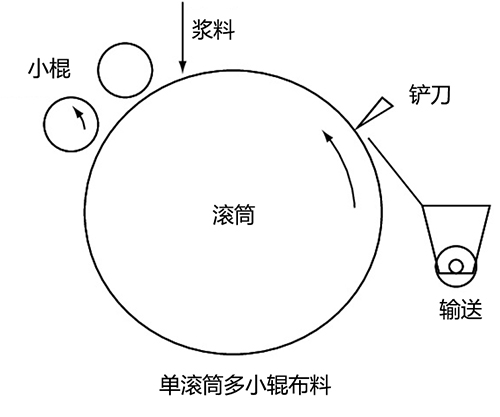

Feeding Type Drum Dryer, Single Drum with Multiple Applicators

Suitable for drying medium-high viscosity and high-concentration slurry. Its uniform thin film is formed by the crushing effect of the small rollers at the top, effectively preventing slurry agglomeration. It is suitable for drying various foods. The small drums are available in 2-7 pieces to accommodate different materials and finished products' wide range of uses.

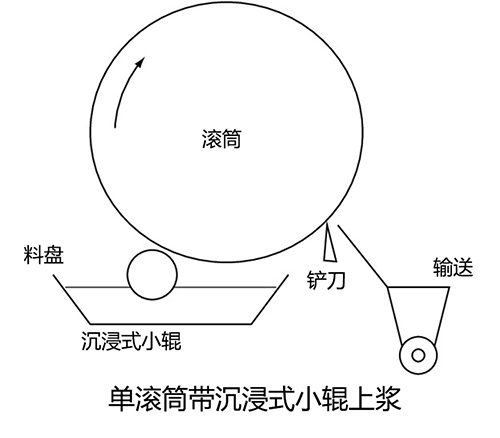

Immersive Coating Single Drum Dryer

Suitable for drying low-concentration and low-viscosity heat-sensitive materials, mainly used for drying yeast broth, feed, pigments, and various chemical raw materials, and environmental protection products.

Nozzle Coating Single Drum Dryer

Suitable for drying medium-concentration and low-viscosity heat-sensitive materials, mainly used for drying concentrated fruit and vegetable juices, eggs, and Chinese herbal medicine.

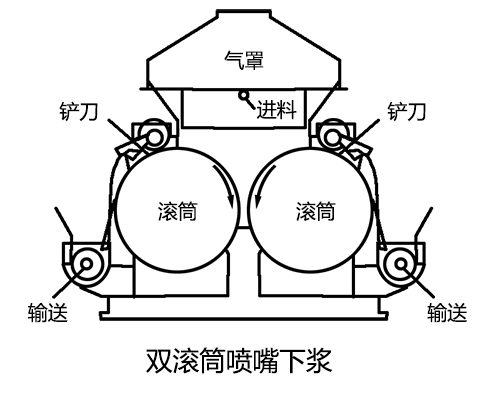

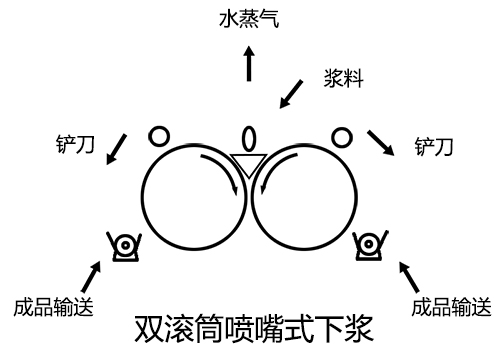

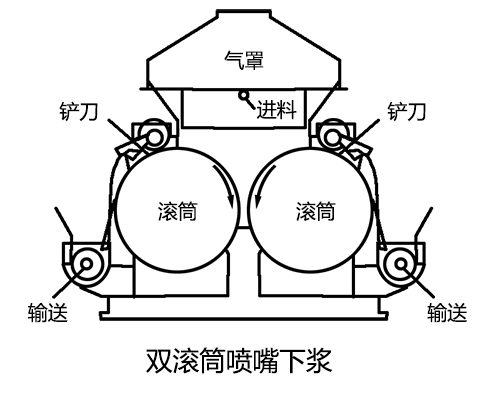

Feeding Type Double Drum Dryer, Meshing Double Drum Dryer

Suitable for drying low-viscosity, high-moisture liquids, mostly used in the chemical and environmental protection industries.

Double drum dryer with multiple

applicators

Suitable for drying various

materials, it is an organic combination of single and double-drum dryers. It

features well-finished product quality, fresh color, and adjustable thickness.

Non-meshing double drum dryer

Suitable for drying

low-viscosity, high-moisture liquids, it is more commonly used in the chemical

and environmental protection industries.